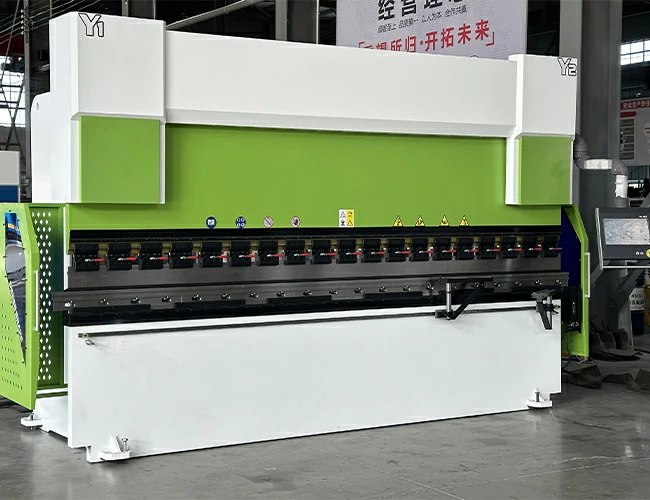

CNC Hydraulic Press Brake supplier

- We have a three-year warranty. These include installation assistance, training, maintenance, and technical support.

- Our machines are capable of precision control, programmable settings, and automation capabilities.

- We offer free customization options such as color and configuration.

Machine Accessories

Hydraulic clamping

Holds the metal sheet securely in place during the bending process. It ensures that the material does not move, which is critical for accurate bends.

Front support

The front support provides a stable platform to hold the metal sheets during bending. It helps prevent the workpiece from sagging or deforming, especially with large sheets.

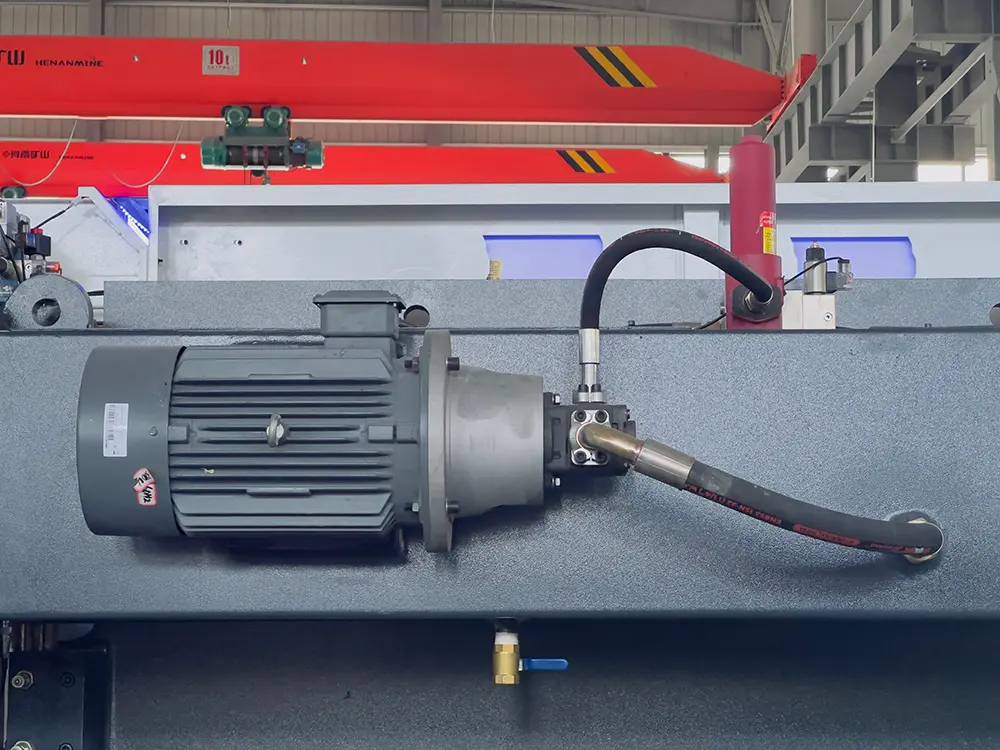

Hydraulic system

The electronic interface used to program and control the press brake. It manages parameters such as bend angle, backgauge position, and the number of bends.

Brake motor

The motor contributes to the overall performance of the press brake, affecting the speed and efficiency of the bending process. A well-maintained motor ensures smooth operation and reliable performance.

Foot pedal or control buttons

Used by the operator to control the machine's operations, including starting and stopping the bending process.

Safety guards

Enclosures around the press brake to protect operators from moving parts and potential hazards. They are crucial for maintaining a safe working environment.

A green bending revolution is underway

With a 15kW motor, you can save up to 56 kWh of electricity every day. That’s 1,680 kWh per month and an impressive 20,160 kWh annually. Significant savings in energy mean lower operating costs and a greener future.

Efficient

Energy Saving

Low Noise

Environment Protection

Our Other Machines

Metal Fiber Laser Cutting Machine

Handheld Laser Welding Machine

Fiber Laser Cleaning Machine

- High Precision: Enhanced accuracy in bending operations.

- Efficiency: Increased bending times by up to 30% compared to traditional press brakes.

- Versatility: Suitable for complex shapes and multiple materials.

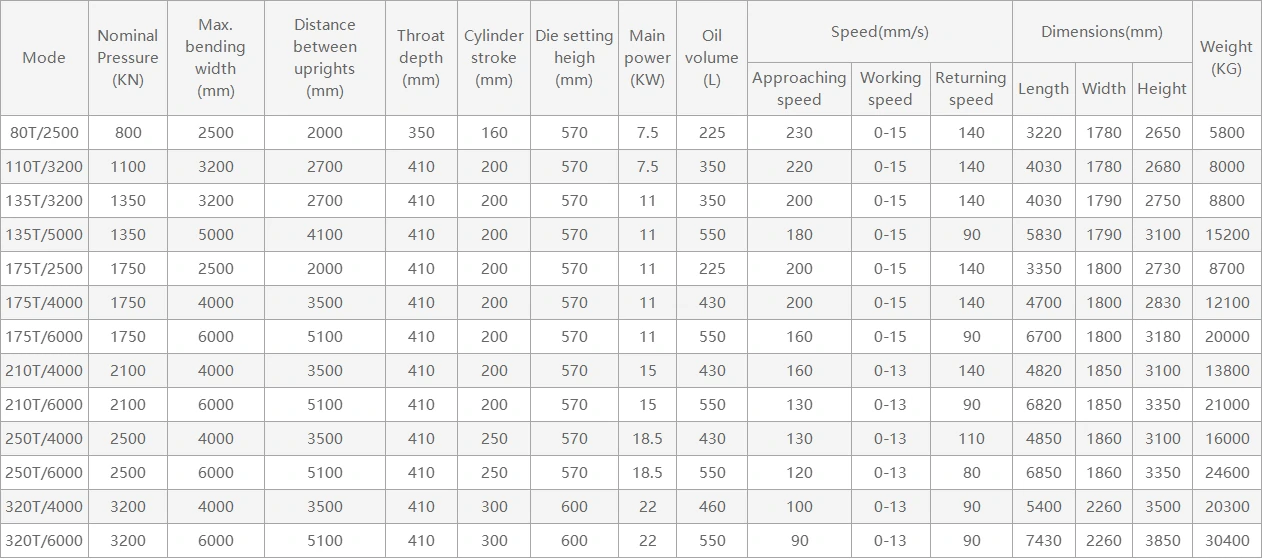

- Material to be Processed: Consider the type and thickness of the metal you need to process.

- Bending Length: Choose an appropriate working length based on the maximum size of the workpiece.

- Pressure Requirements: Select the suitable pressure based on the material’s thickness and strength.

- Accuracy Requirements: Consider the precision needed for processing and choose the corresponding control system.

- Production Efficiency: Evaluate your daily production needs and select the appropriate level of automation.

- Budget: Choose the most cost-effective equipment that meets your requirements.

Our press brakes are designed with a focus on user interaction, making them relatively easy to operate. However, to fully utilize the equipment’s capabilities and ensure safe operation, we recommend that operators undergo professional training. ZLTECH offers comprehensive training services, covering basic operation, programming, and daily maintenance.

Before placing an order, ZLTECH’s sales team engages in detailed communication to understand your specific requirements. They recommend a machine configuration tailored to your needs, ensuring you purchase the most suitable machine for your business. Their priority is to provide the best solution rather than the most expensive one.

Yes, all press brakes from ZLTECH strictly adhere to international safety standards, including CE certification and ISO standards. Our equipment is equipped with multiple safety protection devices, such as photoelectric protection and emergency stop buttons, to ensure the safety of operators.